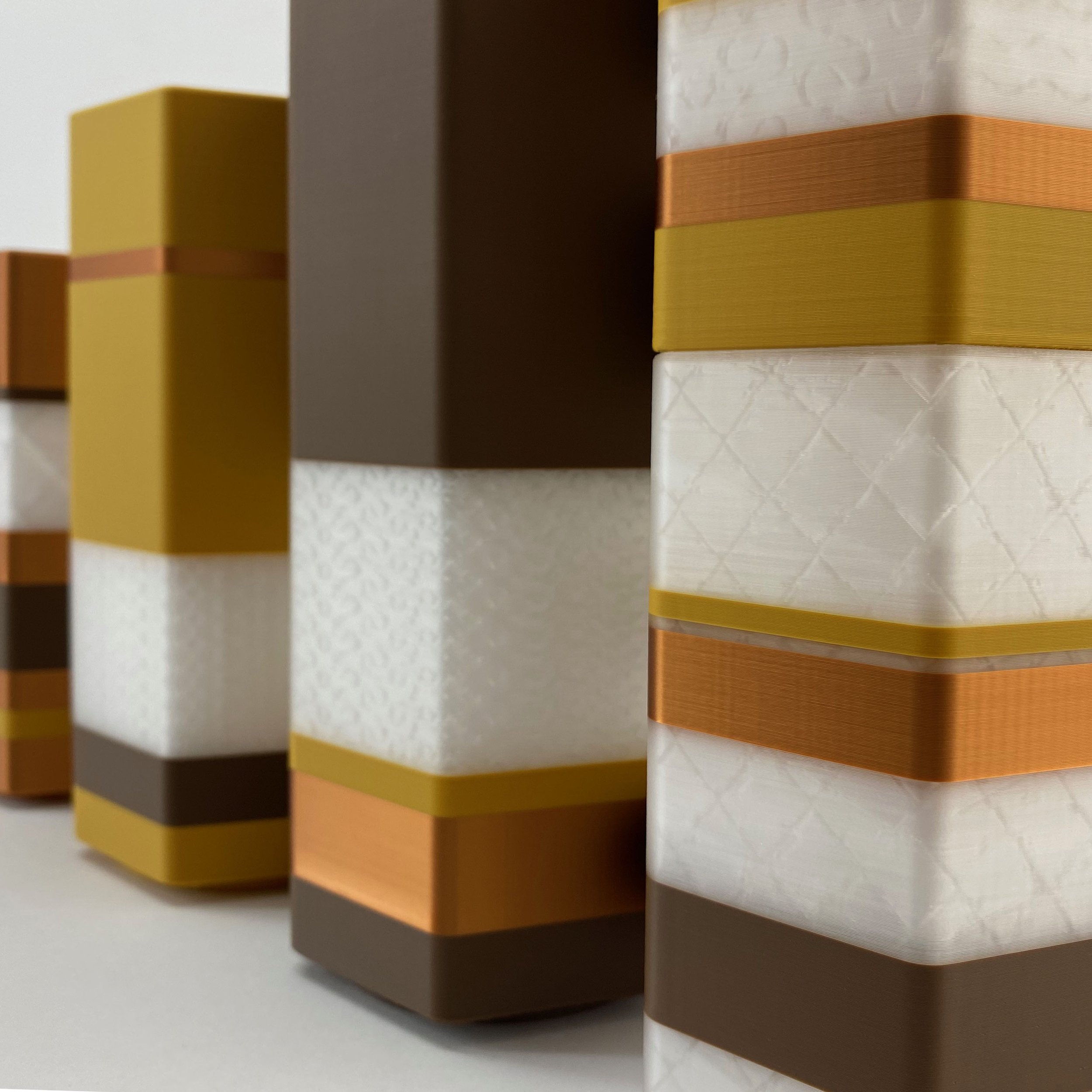

Printable Objects

Who We Are

Based in Tokyo, we are a digital brand offering simple, elegant homewares designed for desktop 3D printing. Our products are the digital files required to 3D print our designs.

Sustainable Production

Desktop 3D printing offers a sustainable alternative to traditional mass production by enabling products to be made locally and on demand: make only what is needed, where it’s needed, and when it’s needed. This minimizes overproduction, manufacturing waste, disposable packaging, discarded excess inventory, and emissions from shipping and warehousing.

Sustainable Materials

PLA, the most widely used 3D printing material, is derived from renewable resources like cornstarch or sugarcane. Its production has a lower carbon footprint than petroleum-based plastics and is recyclable and industrially compostable.

Our Mission

As desktop 3D printers are becoming more reliable and accessible, and the materials they use more advanced, our goal is to promote their adoption as a localized manufacturing solution. This includes advocating for infrastructure development to properly reuse, recycle, or compost 3D printing materials. As designers, we promote the proliferation of 3D printing by creating simple, desirable homewares and furniture that can be easily 3D printed at home or by local 3D printing shops.

The Designer

Giovanni Pellone is a multi-cultural industrial designer and creative director.

He was raised in Rome, where he studied industrial technology and economics; he developed his passion for design in New York, where he studied interior design at Parsons School of Design and industrial design at Pratt Institute; and for the past several years he has been running a design office in Tokyo.

Soon after graduating from Pratt, he established his first design partnership in NYC. In the following years, he designed consumer products, laboratory equipment, trade show displays, advertising, packaging, and visual branding programs. He has been working across design disciplines ever since.

He later was the co-founder of Benza, a Brooklyn-based home accessories brand, of which he became the Creative Director and General Manager. His total involvement at Benza gave him hands-on experience with manufacturing, marketing, and distribution, but also allowed him to collaborate with many talented designers, and to see his work in prestigious retailers worldwide, from the MoMA Design Store in NYC to Harrods in London, and Idee in Tokyo.

His many design projects include accessories for the MoMA Design Store, lighting for Design Within Reach, and packaging for L’Oreal. His work has appeared in design exhibitions at the Museum of Modern Art in New York and Milano Fuorisalone; and has received design awards, including the New York Art Director’s Club Award. His name is listed in The Design Encyclopedia published by MoMA. He has been a visiting lecturer at leading universities in the USA and Japan, including Pratt Institute and Tokyo University.

His current work focuses on the sustainable design of 3D printable furniture, housewares, and home decor.

Sustainable Advantages of Desktop 3D Printing

Compared to traditional mass manufacturing and distribution methods, desktop FDM (Fused Deposit Modeling) 3D printing with PLA (Polylactic Acid) offers a range of advantages and environmental benefits. These advantages span process efficiency, material sustainability, and tailored solutions, which make it a far more sustainable alternative.

Process Efficiency

Reduced Material Waste:

Desktop FDM 3D printing is an additive manufacturing process, meaning the material is deposited layer by layer, using only what is needed. This contrasts with subtractive methods, such as die-cutting and machining, which waste material during cutting and shaping processes.

Reduced Need for Specialized Tools:

A desktop FDM 3D printer can produce diverse designs without requiring molds or tooling. This eliminates the energy and resource consumption involved in creating specialized equipment for mass production.

No Overproduction:

Instead of mass manufacturing large quantities of products in anticipation of demand, desktop FDM 3D printing enables localized production, creating items only when and where they are needed. This minimizes overproduction and inventory waste typically associated with mass manufacturing.

Energy Efficiency:

Especially for small-scale production or custom items, desktop FDM 3D printing consumes less energy compared to industrial-scale manufacturing processes, which require significant energy for setting up and running high-volume machinery.

Lower Transportation Emissions:

As a form of distributed manufacturing, desktop FDM 3D printing produces items locally, near their point of use. This reduces the carbon emissions associated with shipping and distribution networks required by centralized mass production.

Minimized Packaging:

Since desktop FDM 3D printing allows items to be produced locally, there is significantly less need for product packaging, shipping cartons, shipping crates, and all other packaging materials needed to move a product from a factory to its final home.

Material Sustainability

Renewable Material:

PLA (Polylactic Acid) is a bioplastic made from renewable resources, such as cornstarch or sugarcane. Its production also has a lower carbon footprint compared to petroleum-based plastics commonly used in mass production.

Biodegradability of PLA:

PLA is biodegradable under industrial composting conditions, providing a more environmentally friendly alternative to non-recyclable plastics. While it requires specific facilities to decompose, its biodegradability represents a significant step toward sustainable polymers.

Recycling Possibilities:

Failed or unused PLA prints can be shredded and recycled into new filament with the right equipment, closing the material loop and further minimizing waste.

Tailored Solutions

Repair and Replacement Parts:

Desktop FDM 3D printing enables the cost-effective and localized production of customized replacement parts, extending the lifespan of products and reducing the need to replace entire systems.

Ease of Customization:

The lack of tooling in desktop FDM 3D printing allows for easy customization during the design and printing stages, enabling personalized dimensions and features tailored to specific needs.

Efficient Innovation:

With desktop FDM 3D printing, designers and makers can create and iterate prototypes locally. This eliminates the environmental costs associated with outsourcing prototyping and tooling to centralized facilities.

By combining localized production, renewable materials, and design flexibility, desktop FDM 3D printing with PLA offers significant advantages and a more sustainable path forward compared to traditional manufacturing methods. It empowers individuals and businesses to produce responsibly while reducing their environmental impact.